- Can replace the inefficient manual powder transportation mode and be directly applied to the transportation of solid powder to reduce air pollution and raw material waste

- Adopts the fully closed transportation mode to directly transport the powder from the raw material container to the receiving container at the formula, so as to reduce dust pollution in the working environment and ensure personal safety

- Maximum bulk density of transporting powder can reach 0.8g/cm3, the maximum siphon height can reach 5m, and the maximum transporting capacity can reach 5,500Kg/h

- Intermittent high efficiency airflow induced fluidization system can optimize the material and gas ratio, reduce gas consumption and material gas-solid ratio, and prevent powder accumulation;

- Separated fluidizing gas and driving gas can avoid the oxidation and deliquescence of the material in contact with the air and the gas in contact with the powder can be further purified and dried separately, or use other gases.

- Can replace air mixed transportation, screw transportation and scraper transportation

- can continuously transfer dry powder with specific gravity up to 0.8g/cm3 without failure, such as carbon black, pigment powder, combustion supporting agent, expanded mica, silicone, acrylic resin, 3D printing powder, silicone resin and pharmaceuticals, etc.

Characteristic

New perfect powder transportation equipment with low failure rate

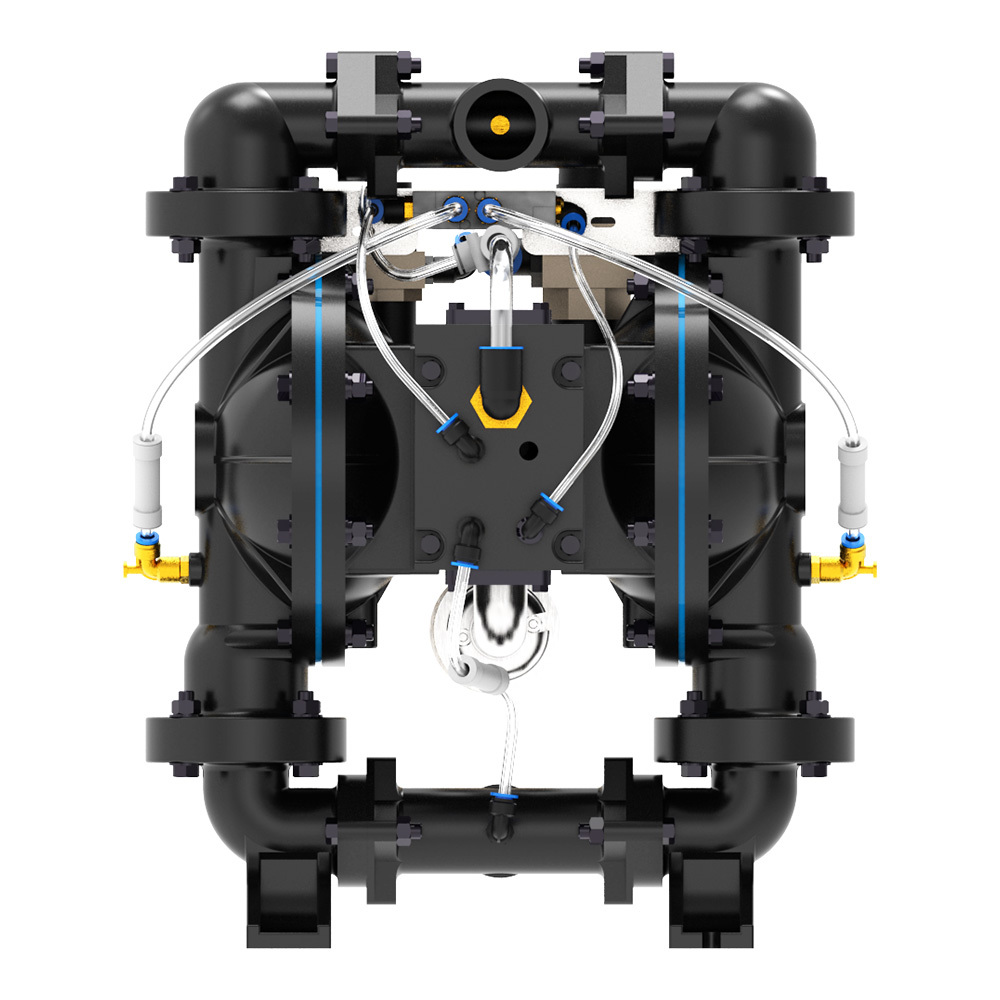

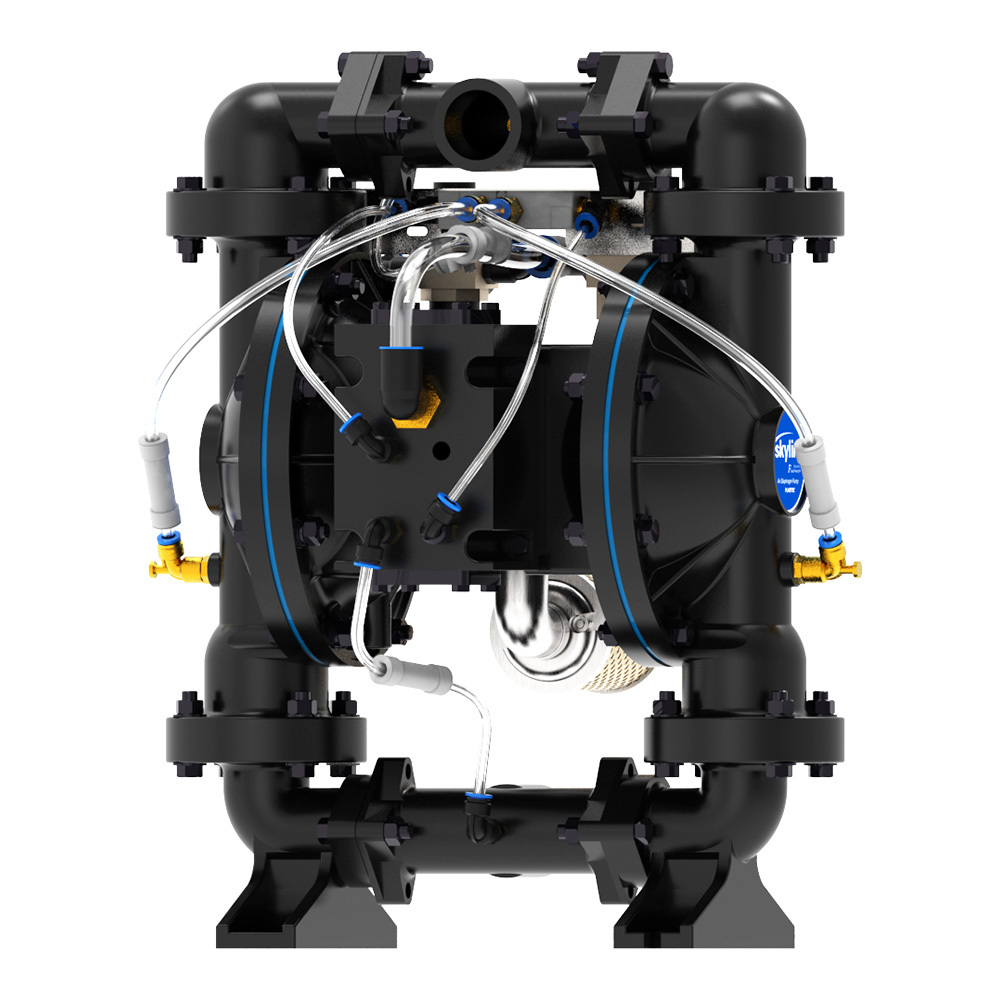

Dimensions

Material

| MATERIALS | PART |

|---|---|

| Material of wetted parts | Aluminum alloy, 316L stainless steel |

| Material of non-wetted parts | Aluminum alloy(electrophoresis) |

| Air valve | Aluminum alloy(electrophoresis) |

| MATERIALS | PART |

|---|---|

| Santoprene | -40°C to 107°C (-40°F to 225°F) |

| Neoprene | -18°C to 93°C (0°F to 200°F) |

| Polytetrafluoroethylene (PTFE) | 4°C to 104°C (40°F to 220°F) |

| Nitrile rubber (Buna-N) | -12°C to 82°C (10°F to 180°F) |

| EPDM | -51°C to 138°C (-60°F to 280°F) |

| Fluorine rubber (FKM) | -40°C to 177°C (-40°F to 350°F) |

Accessories

Send A Message

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

English

English  español

español 中文

中文